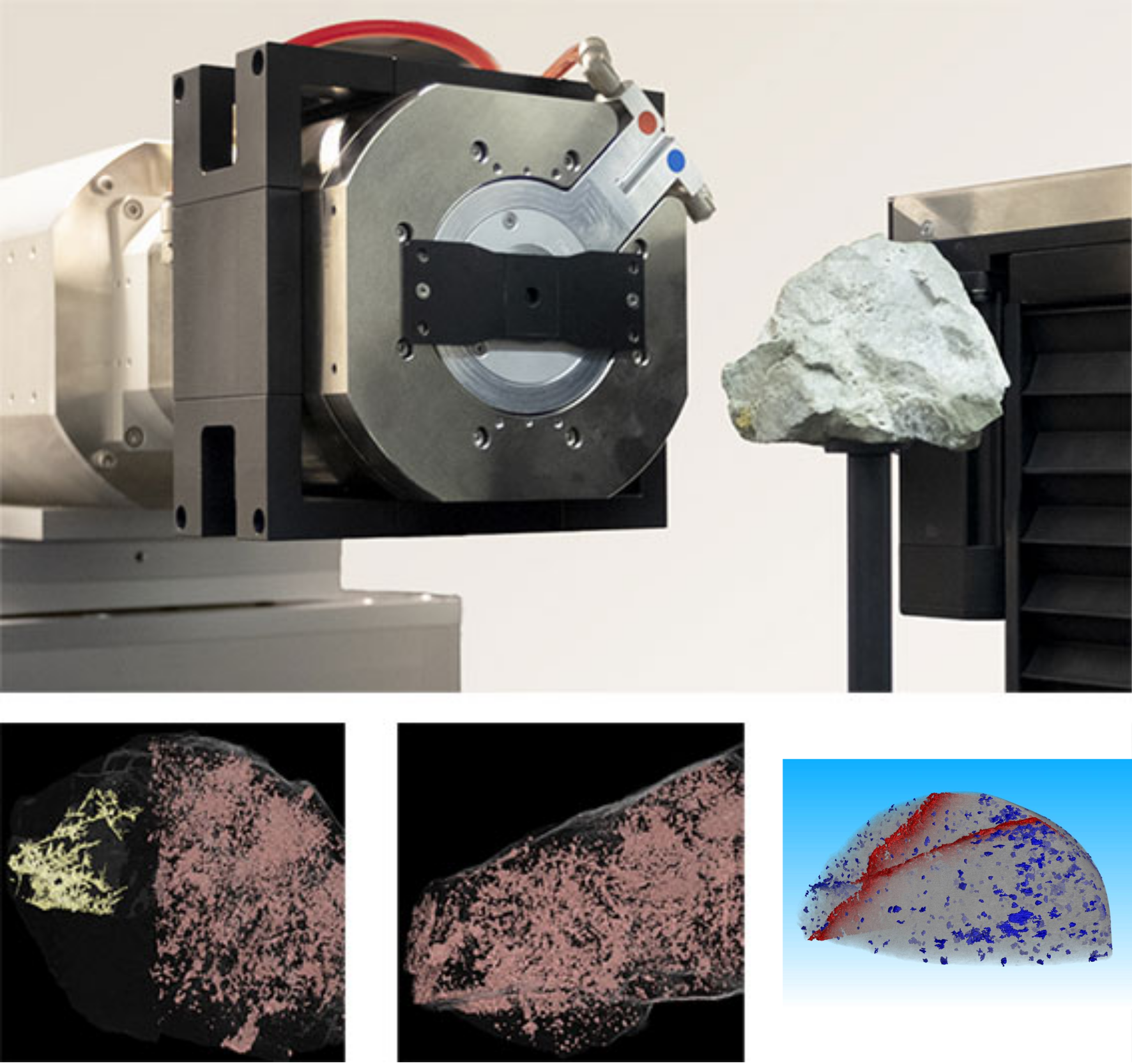

Industrial Computed Tomography

Computed Tomography (CT) is a non-destructive X-ray computerized method for studying the microstructure of multicomponent materials and constructions in a 3D regime. It is currently the only method that allows the observation and analysis of internal and external microstructures of sample objects, both organic and inorganic, with no sample preparation requirements (such as sectioning and grinding) and without strong limitations on the size and shape of the objects studied (compared to other high-resolution imaging techniques). CT can be used to detect the internal design of different components of a sample object – such as grain sizes, inclusions, distortions, inhomogeneity, and defects (porosity, cracks) – supported by the digital reconstruction of the 3D images. Since January 2020, a newly established CT laboratory is operational at the Institute of Mineral Resources Engineering (MRE), RWTH Aachen University. The acquired CT-scanner „ProCon CT-Alpha“ is designed to meet the requirements from various fields of research, including the geological, biological and archaeological sciences and engineering disciplines. It can be used to establish the micro-structure of ores, rocks, fossils, concrete and construction materials and applied to material and damage analysis of manufactured goods including plastics, wood-based materials, building materials, metals and composite hybrid materials.

Technical Specifications

- X-ray tube of model „XWT-240-TCHE Plus“, energy range of source up to 240 kV

- Power up to 50 W

- Detector system XRD 1611 AP3, having 4064 x 4064 Pixel, each pixel is 100 μm

- Down to 3 micron voxel size

- 5-axis system X-Y-Z-rotation-rilting for fine positioning

- Different W-targets for high resolution and performance regimes

- Software: VG Studio MAX 3.5, ORS Dragonfly 2022.1

- 3D-printer for manufacturing of high-precision sample holders

Sample requirements

- Max sample size: 60 cm (greatest extension)

- Specimen weight: max. 15 kg

Application

- Visualisation and rendering of minerals, ores, rocks, fossils, residuals, building materials (e.g. concrete), fibre composites, etc in 3D.

- Quantitative analysis of the microstructure such as mineral distribution, grain size, pore space, grain shape or mineral volumina

Publications

Krebbers, L., Gainov, R., Lottermoser, B. G., Lohmeier, S., & Hennig, A. (2021). Applications of Industrial Computed Tomography in the Mining Sector. Mining Report, 157(4).

Gainov RR, Lottermoser BG, Kolobov S, Szabo G. Computed tomography of gold ore from the Porgera mine, Papua New Guinea: implications for acid rock drainage prediction. Book of Abstracts of the 10th Conference on Industrial Computed Tomography, Wels, Austria (iCT 2020), pp.215-216.

Gainov RR, Faidel D, Behr W, Natour G, Pauly F, Willms H, Vagizov FG Investigation of LPBF A800H steel parts using Computed Tomography and Mössbauer spectroscopy. Additive Manufacturing, 2020, vol. 32, 101035.

Flyer